On this page:

How do we hear?

What sounds cause NIHL?

What are the effects of NIHL?

What are the symptoms of NIHL?

Who is affected by NIHL?

Can NIHL be prevented?

What research is being done for NIHL?

Where can I get additional information?

Every day we experience sound in our environment such as the television, radio, washing machine, automobiles, buses, and trucks. But when an individual is exposed to harmful sounds--sounds that are too loud or loud sounds over a long time--sensitive structures of the inner ear can be damaged, causing noise-induced hearing loss (NIHL).

How do we hear?

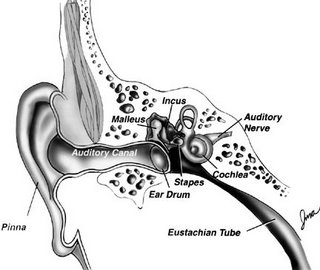

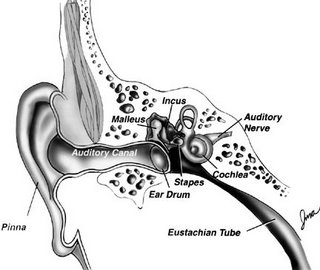

Hearing is a series of events in which the ear converts sound waves into electrical signals that are sent to the brain and interpreted as sound. The ear has three main parts: the outer, middle, and inner ear. Sound waves enter through the outer ear and reach the middle ear where they cause the eardrum to vibrate.

The vibrations are transmitted through three tiny bones in the middle ear, called the ossicles. These three bones are named the malleus, incus, and stapes (and are also known as the hammer, anvil, and stirrup). The eardrum and ossicles amplify the vibrations and carry them to the inner ear. The stirrup transmits the amplified vibrations through the oval window and into the fluid that fills the inner ear. The vibrations move through fluid in the snail-shaped hearing part of the inner ear (cochlea) that contains the hair cells. The fluid in the cochlea moves the top portion of the hair cells, called the hair bundle, which initiates the changes that lead to the production of nerve impulses. These nerve impulses are carried to the brain, where they are interpreted as sound. Different sounds move the hair bundles in different ways, thus allowing the brain to distinguish one sound from another, such as vowels from consonants.

What sounds cause NIHL?

NIHL can be caused by a one-time exposure to loud sound as well as by repeated exposure to sounds at various loudness levels over an extended period of time. The loudness of sound is measured in units called decibels. For example, normal conversation is approximately 60 decibels, the humming of a refrigerator is 40 decibels, and heavy city traffic noise can be 85 decibels. Examples of sources of loud noises that cause NIHL are motorcycles, firecrackers, and firearms, all emitting sounds from 120 to 150 decibels. Sounds of less than 80 decibels, even after long exposure, are unlikely to cause hearing loss.

Exposure to harmful sounds causes damage to the sensitive hair cells of the inner ear as well as the hearing nerve. These structures can be injured by two kinds of noise: loud impulse noise, such as an explosion, or loud continuous noise, such as that generated in a woodworking shop.

What are the effects of NIHL?

Impulse sound can result in immediate hearing loss that may be permanent. The structures of the inner ear may be severely damaged. This kind of hearing loss may be accompanied by tinnitus, a ringing, buzzing, or roaring in the ears or head, which may subside over time. Hearing loss and tinnitus may be experienced in one or both ears, and tinnitus may continue constantly or occasionally throughout a lifetime.

Continuous exposure to loud noise also can damage the structure of the hair cells, resulting in hearing loss and tinnitus. Exposure to impulse and continuous noise may cause only a temporary hearing loss. If the hearing recovers, the temporary hearing loss is called a temporary threshold shift. The temporary threshold shift largely disappears 16 to 48 hours after exposure to loud noise.

Both forms of NIHL can be prevented by the regular use of hearing protectors such as earplugs or earmuffs.

What are the symptoms of NIHL?

The symptoms of NIHL increase gradually over a period of continuous exposure. Sounds may become distorted or muffled, and it may be difficult for the person to understand speech. The individual may not be aware of the loss, but it can be detected with a hearing test.

Who is affected by NIHL?

More than 30 million Americans are exposed to hazardous sound levels on a regular basis. Individuals of all ages, including children, adolescents, young adults, and older people, can develop NIHL. Exposure occurs in the workplace, in recreational settings, and at home. Noisy recreational activities include target shooting and hunting, snowmobiling, riding go-carts, woodworking and other noisy hobbies, and playing with power horns, cap guns, and model airplanes. Harmful noises at home include vacuum cleaners, garbage disposals, gas-powered lawn mowers, leaf blowers, and shop tools. And it makes no difference where a person lives--both urban and rural settings offer their own brands of noisy devices on a daily basis. Of the 28 million Americans who have some degree of hearing loss, about one-third can attribute their hearing loss, at least in part, to noise.

Can NIHL be prevented?

NIHL is preventable. All individuals should understand the hazards of noise and how to practice good health in everyday life.

- Know which noises can cause damage (those above 85 decibels).

- Wear earplugs or other hearing protective devices when involved in a loud activity (special earplugs and earmuffs are available at hardware stores and sporting good stores).

- Be alert to hazardous noise in the environment.

- Protect children who are too young to protect themselves.

- Make family, friends, and colleagues aware of the hazards of noise.

- Have a medical examination by an otolaryngologist, a physician who specializes in diseases of the ears, nose, throat, head, and neck, and a hearing test by an audiologist, a health professional trained to identify and measure hearing loss and to rehabilitate persons with hearing impairments.

What research is being done for NIHL?

Scientists are studying the internal workings of the ear and the mechanisms that cause NIHL so that better prevention and treatment strategies can be developed. For example, scientists have discovered that damage to the structure of the hair bundle is related to temporary and permanent loss of hearing. When the hair bundle is exposed to prolonged periods of damaging sound, the basic structure of the hair bundle is destroyed and the important connections among hair cells are disrupted. These structural changes lead directly to hearing loss.

Recent NIDCD research

Recent findings by NIDCD researchers show that hair bundles are capable of rebuilding their structure from top to bottom over a 48-hour period (the common duration of temporary hearing loss). Researchers suggest that permanent hearing loss may occur when damage is so severe that it overwhelms the self-repair mechanism. 1

1 Schneider M.E., Belyantseva I.A., Azevedo R.B., Kachar B. Rapid renewal of auditory hair bundles. Nature. 22 Aug 2002. 418(6900): 837-838.

Drug therapies

Other studies involve potential drug therapies for NIHL. For example, scientists are studying how changes in blood flow in the cochlea affect hair cells. When a person is exposed to loud noise, blood flow in the cochlea drops. However, a drug that is used to treat peripheral vascular disease (any abnormal condition in blood vessels outside the heart) maintains circulation in the cochlea during exposure to noise. These findings may lead to the development of treatment strategies to reduce NIHL.

Continuing efforts will provide opportunities that can aid research on NIHL as well as other diseases and disorders that cause hearing loss.

http://www.nidcd.nih.gov/health/hearing/noise.asp

<--

<--

On this page:

On this page: