Taking Stock Takes Tragic Turn

Tasked to take stock, a worker had squeezed into a gap between racks of goods to take count. In a tragic turn of events, he was crushed to death when a forklift pushed the racks closer.

The Ministry of Manpower (MOM) immediately instructed the occupier to stop all operations in the premises. Investigation has commenced and is still in progress. The occupier was also instructed to conduct risk assessment on all types of work and develop safe work procedures.

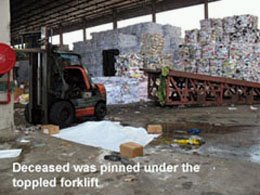

Toppled Forklift Takes a Life

The second day on the job sadly marked the end of a young forklift driver. The 25-year-old worker was killed instantly when the forklift he was operating toppled off a ramp.

The Ministry of Manpower immediately instructed the occupier to stop all forklift operations in the premises. Investigation has commenced and is still on-going.

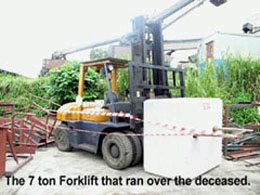

Worker Ran Over by Forklift

A short nap near a vehicle access road (part of a T-junction) by a 30-year-old worker, turned fatal when he

was run over by a forklift. The worker, a painter/grinder, who was lying next to a steel fabricated block died on the spot.

was run over by a forklift. The worker, a painter/grinder, who was lying next to a steel fabricated block died on the spot.The occupier was instructed to review all forklift operations and plant maintenance in the yard. Investigation is still on-going.

Advisory Note - Eight Safety Tips for Forklifts

(Please note that the advisory note is provided for the benefits of enhancing workplace safety and health, in no way the information is to be misconstrued as implying any liability on any party)

Forklifts are powerful machines that if handled improperly can turn into deadly weapons. Here are eight tips to bear in mind for the safe handling of forklifts:

- Check to ensure that the forklift driver is properly qualified to operate a forklift and has undergone all mandatory training before employment.

- Undertake all safety procedures including pre-use checks before starting to use the forklift.

- Avoid shock-loading/over-loading forklifts.

- Do not use forklifts for the wrong purposes; as bulldozers, or elevators, for example.

- Never drive an unloaded forklift with the forks raised and drive at a safe speed.

- Never disable the safety features such as seat safety switches and reversing beepers to avoid annoyance. Regular forklift maintenance must be carried out.

- Access routes for workers and forklifts must be clearly marked and separated whenever practicable.

- There must be proper work coordination to ensure that materials or objects handled by the forklift do not pose hazard to other workers.

To ensure that comprehensive risk assessment and proper safety measures are in place for forklift operations, the MOM's Occupational Safety and Health (OSH) inspectors will be intensifying their checks on forklift operations with effect from 10 July 2006.

Click on the following to read the MOM press release on forklift operation:

http://www.mom.gov.sg/PressRoom/PressReleases/20060703-MOMtargetsforkliftoperationstoimproveworkplacesafety.htm

The Workplace Safety and Health Advisory Committee (WSHAC) has designed a checklist for efficient and safe forklift operation. Click the following to download the checklist:

http://www.mom.gov.sg/NR/rdonlyres/76133C9E-00E6-4A32-94B7-232AEB9D3932/10600/Checklistonforkliftoperations_Jun2006.pdf

From Ministry of Manpower, Singapore in the OSH Alert dated 6 July 2006